PF1 FULL ELETRIC FACING MACHINE ADVANTAGES

PF1 FULL ELETRIC FACING MACHINE ADVANTAGES

• Max torque at low speed cutting speed – for CRA pipe

• Extremely high precision on the cutting parameters

• 100% cutting parameter repetition from time to time via programmable PLC

• Increased level of automation permitting the use of multiple stations by only one operator

• Completely integrable with the vessel including wide parameters backlog

• Highly improved safety using electric cable instead of hydraulic hoses

• Lower skills needed by the operator

• Remote assistance/service available

• Reduced number of operators needed (one operator can control more

machines)

• Reduced power consumption

• Possibility to work for 40min without feeding

• NO MORE OIL and HOSES and no more cumbersome HPUs onboard

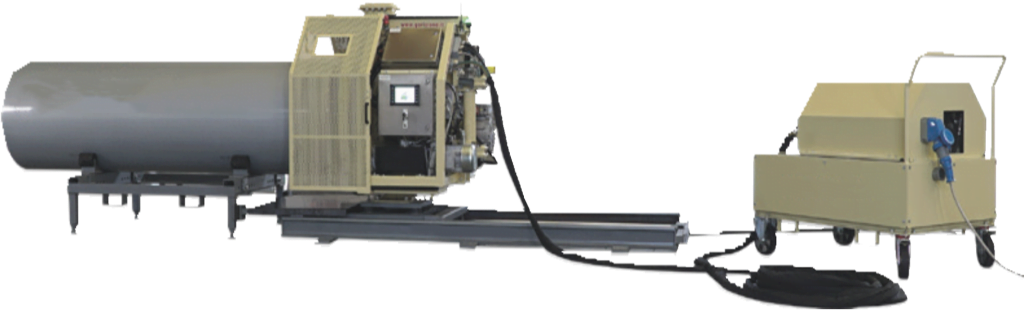

TOMORROW’S TECHNOLOGY TODAY. THE AUTOMATIC BEVELLING STATION IS HERE.

The PF1 have been re-engineered from Hydraulic to ELECTRIC by using automotive technologies. Hydraulic PF1 can be also converted in ELECTRIC with the dedicated conversion kit.

The electric pipe facing machine gives enormous advantages to the operator in terms of performance, simplicity, repeatability of the process and flexibility.

The electric pipe facing machine allowed GORIZIANE to develop the AUTOMATIC BEVELLING AREA, by implementing with automation on: positioning cradles, chips removal, changing tool, bevel scan, measurement and reporting for best fitting, deburring and grinding.