Jacket Pile Grippers

DESIGN

- Sizeable to any pile diameter

- Balanced design in number of cylinders versus gripping capacity

- Ring height sufficient to limit heat affected zone close to cylinder fittings and hydraulics during installation (welding) at yard

- Compliant to standards and 3rd party Design Approval (DAD)

FEATURES

Tailored to jacket design and offshore installation methodology, allowing for

- Clearance for hammer and drilling equipment

- The installation (and clearance) of levelling equipment

- The placement of the grout

OPERATION

- Hydraulically operated with fail-safe

- Operation redundancy – from surface and/or ROV-panel

- Ability to re-grip by dual-acting cylinders

INSTALLATION

- FAT and packed ready for shipment at fabrication site

- Transport can be arranged for

- Optional on-site installation support, commissioning and SAT

Examples / Proposals

HVDC-Platform Centre Manche

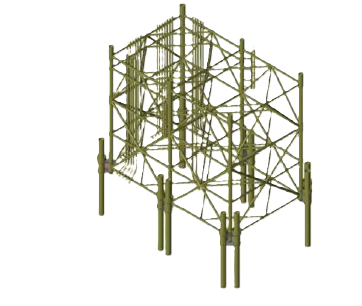

2GW-Platform TENNET/AMPRION

Project Input

Centre Manche

CASE – OFFSHORE SUBSTATION

Tailored to jacket design and offshore installation methodology, allowing for

- 6 legs

- 10 pile sleeves

- Jacket weight 5,250T excl. piles

- Pile diameter 2,438mm (96”)

- Pile sleeve diameter 2,890mm

GRIPPING SCENARIOS

| Scenario | Pile Grippers (#) | Max Horizontal / Force Fh,max (t) | Max. Vertical / Force Fv,max (t) |

| Pile gripper per pile sleeve | 10 | 242.64 | -993.96 |

| Pile gripper per leg | 6 | 298.43 | -1043.39 |

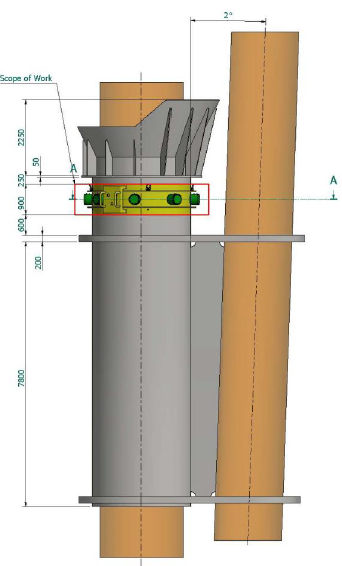

Design – Centre Manche

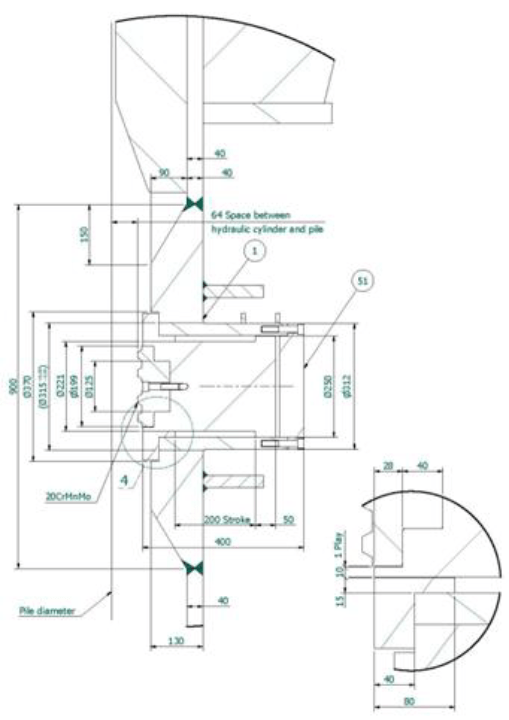

PILE GRIPPER – STRUCTURE

- Scenario one (1) gripper per leg (6 total)

- Eight (8) hydraulic jacks for sufficient clamping force

- No vertical adjustment capability

- Funnel and sleeves are not part of scope

- Grippers to be installed (welded) upon jacket at yard

- Ring height sufficient to limit heat affected zone during installation (welding) close to hydraulics and fitting of jacks

DESIGN ALLOWS FOR:

- Clearance for hammer and drilling equipment so underwater cutting of piles is avoided later

- The installation (and clearance) of levelling equipment

- The placement of the grout.

- Base case is one (1) ROV-panel and hot stab per gripper

- Connecting frame on ring to bolt on ROV-Panel

- Standard operating pressure of 250 bar is assumed

- Stab and receptacle have Ø35 hydraulic bores, when used on 8 jacking cylinders act gradually

- Control from surface is optional

EPC Bid – Centre Manche

DETAILS

- 2.438 mm Hydraulic pile gripper

- S355J2 steel

- 8* Ø250 mm * 200mm stroke double-acting hydraulic cylinders

- Hydraulic piping for connections between cylinders and ROV panel

- Necessary NAS 6 Biodegradable hydraulic oil BIOVESTA 46

- Surface treatment SA 21/2 Blasting + 150mm epoxy

- Assembly and factory test

- Load testing TBD with client

- Packaging

SERVICES

- On-site support for fitting and commissioning + SAT on day rate

- Class certification on a cost+15% basis

- Transport from fabrication site to construction yard on a cost+15%

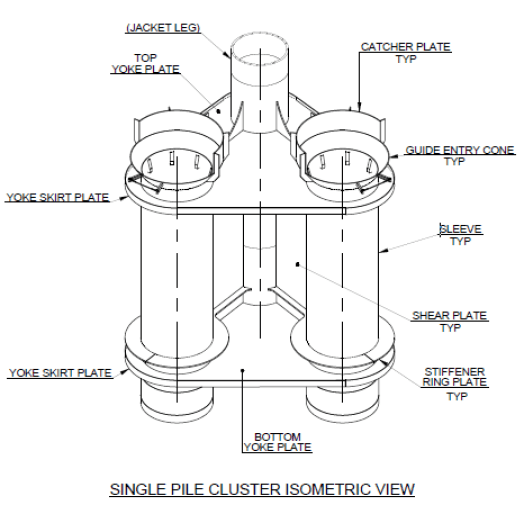

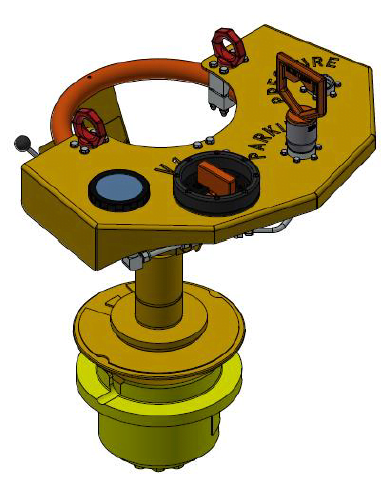

Design – 2GW Platform

PILE GRIPPER – STRUCTURE

- Eight (8) Jacket Pile Grippers per jacket

- Eight (8) hydraulic jacks for sufficient clamping force (8*1,500T)

- No vertical adjustment capability

- Funnel and sleeves are not part of scope

- Grippers to be installed (welded) upon jacket at yard

- Ring height sufficient to limit heat affected zone during installation (welding) close to hydraulics and fitting of jacks

DESIGN ALLOWS FOR:

- Clearance for hammer and drilling equipment so underwater cutting of piles is avoided later

- The installation (and clearance) of levelling equipment,

- The placement of the grout

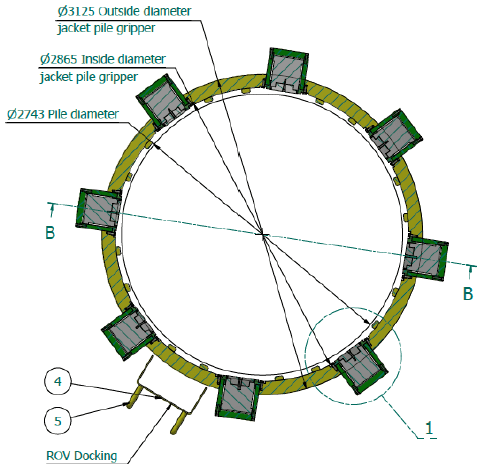

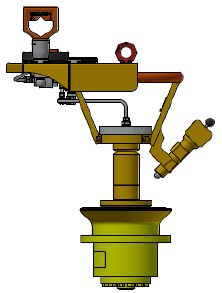

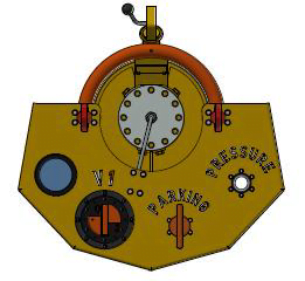

Operation – 2GW Platform

PILE GRIPPER – HYDRAULICS

- Double acting cylinders

- Rigid piping installed on gripper ring to feed jacks

PILE GRIPPER – OPERATION

- Base case is one (1) ROV-panel and hot stab per gripper

- Connecting frame on ring to bolt on ROV-Panel

- Standard operating pressure of 250 bar is assumed

- Stab and receptacle have Ø35 hydraulic bores, when used on 8 jacking cylinders act gradually

- Control from surface is optional

EPC Bid – 2GW Platform

DETAILS

- 3,125 mm Hydraulic Jacket Pile Gripper

- Design / 3 modelling / 2d drawings / FEM and DNV Design Approval

- IOM Manuals and MRB package

- S420 steel

- 8* double-acting hydraulic cylinders

- ROV-Panel

- Hydraulic piping for connections between cylinders and ROV panel

- Rotating hoist rings + Bolts and washers

- Necessary NAS 6 Biodegradable hydraulic oil BIOVESTA 46

- Surface treatment and Sigmacover380 DFT=125μm+Sigmacover456 DFT=125μm (colour TBD)

- Assembly and factory test

SERVICES

- On-site support for fitting and commissioning + SAT against cost+15%

- Transport from fabrication site to construction yard against cost+15%

- Batched transport possible 5*8 dependent delivery schedule

- Load-test and number of tests (test interval) TBD